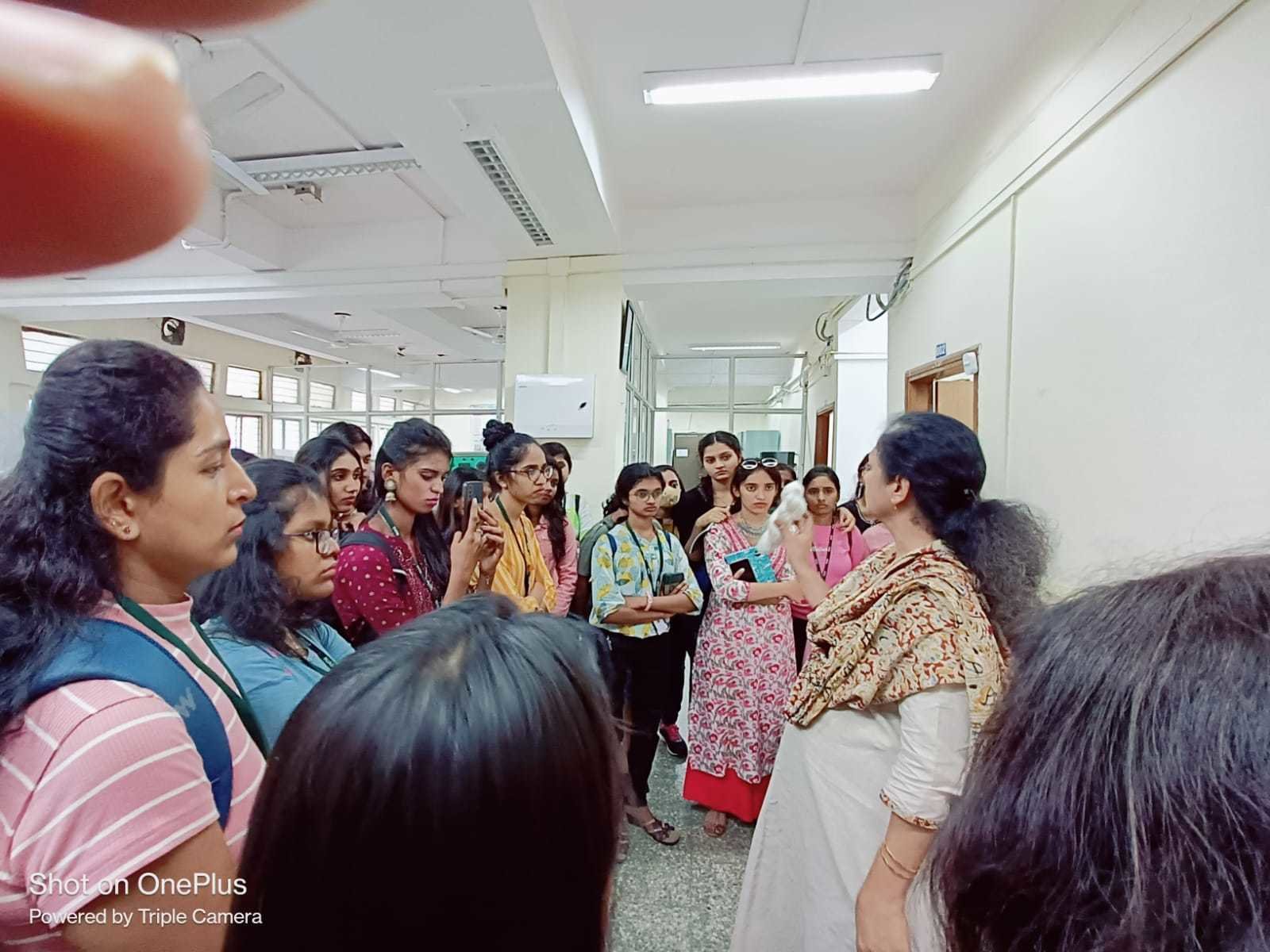

Visit to Central Silk Technological Research Institute (CSTRI)

The central silk board is a statutory body that functions under the administrative control of the Ministry of Textiles. It was established in 1948, today they have around 300 office around the country and its headquarter is in Bangalore. Mr. M. R. Itagi, Scientist-‘D’ from central silk technological research institute led the wonderful journey of production of silk from the cocoon stage to the final beautiful silk fabric. He also briefed out about the wonders of types of silk, cocoon / silk markets’ need for an increase in silk production, and opportunities and promotional activities offered by the Central Govt. India is the 2nd leading producer of silk where 36,000 metric tonnes are produced here. In spite of this huge production, India still imports 4 metric tons of silk from China and other parts of the world. The silk saree business is of 1 lakh crore net worth investment. Karnataka has 63 silk markets and stands as the largest producer of silk in India. The entire silk production has 70% of mulberry silk and 30% of other types of silk produced.

Silk production starts from egg production, and cocoon formation followed by the reeling process, re-reeling process, winding process, doubling process, twisting process, and weaving process. The other types of silk which are produced in India are Muga silk also known as the gold thread which costs Rs 28000 for 1KG, Mulberry silk which costs Rs 6000 for 1Kg, Tussar silk costs Rs 8000 for 1Kg and Eri silk which costs 10000 for 1Kg. Representatives from each production section of the silk fabric manufacturing process from the cocoon stage explained the process in detail. The practical exposure was very informative and useful to the students. The prospects in the silk industry and sericulture department is huge with a lot of subsidies provided by the central government.